*Important Information: As an audience supported website, if you purchase an item after clicking an external link or advertisement marked with an asterisk (*) on this website, we may receive a commission. This does not change the price you pay.

Most lawnmowers on sale today employ a rotary cutting mechanism. Image Credit: Hryshchyshen Serhii

The Cutting Edge

Whilst most lawnmowers on sale in the UK today employ either a rotary or cylinder cutting mechanism - or a variation thereof - other cutting technologies are also available.

Most lawnmowers on sale today employ a rotary cutting mechanism. Image Credit: Hryshchyshen Serhii

Rotary Mowers

Rotary mowers remain the most widely used type of lawn mower on the market today — and for good reason. Their straightforward, mechanical design makes them highly effective, across a broad range of grass types and lawn conditions.

At the heart of every rotary mower is a horizontally mounted, bar-style blade affixed to a vertical crankshaft. When powered by an engine or electric motor, the blade spins rapidly on its vertical axis, cutting grass with a high-speed, machete-like slicing action. Imagine the motion of an inverted helicopter rotor, and you'll get a gist of the dynamics involved.

In higher-end consumer models and professional-grade rotary mowers, the cutting system is often enhanced with a lift fan mounted above the blade. The fan boosts airflow beneath the cutting deck, significantly improving collection efficiency, so more clippings are directed into the collection bag, with fewer left behind on the lawn.

Benefits of a Rotary Mower

As the UK’s top-selling mower type, rotary mowers have earned their popularity through a blend of versatility, practicality, and cost-effectiveness. Their robust yet simple design makes them ideal for most domestic lawns:

- Versatility: Rotary machines can handle most lawn and grass types, from fine turf, to tougher, mixed-species lawns;

- Ease of operation: Simple mechanics and intuitive controls make rotary mowers easy to operate and to maintain;

- Available in a wide range of cutting widths with models available to suit almost any size of lawn;

- Affordability: Rotary mowers usually cost significantly less than comparable cylinder mowers;

- Low maintenance: Rotary blades are durable, inexpensive to replace, and easily maintained;

- Wide range of cutting heights – indeed some rotary mowers come complete with a function to collect and shred fallen leaves;

- Adaptability: Rotary machines can generally handle variable grass conditions, and areas of uneven ground, better than a cylinder mower;

- Lightweight: Rotary models are often lighter than their cylinder counterparts, making them easier to manoeuvre and transport;

- Extensive choice of machines available, including wheeled, roller, hover and mulching models.

Whether you're looking for a budget-friendly, low-maintenance option, or a feature-rich mower for more demanding tasks, rotary mowers offer unrivalled flexibility and choice.

Affordable, requiring little maintenance and easy to use, most lawnmowers sold today feature a rotary cutting mechanism. Image Credit: Author

The cut height of many rotary mowers can be adjusted, to shred fallen leaves - a useful function during the autumn months.

Image Credit: Bild Wasser

Disadvantages of a Rotary Mower

While rotary mowers will excel on most lawns, for some specialist applications, other cutting technologies may be preferred:

- Quality of cut: Rotary blades deliver a high-speed chopping action, rather than the fine scissor-like cut of a cylinder mower. As a result, the finish may lack the uniformity and sharpness required for use on ornamental lawns;

- Limited low-cut capabilities: Rotary mowers typically cannot achieve the ultra-low cutting heights demanded for fine turf applications, such as greens and bowling lawns. At applications where a precision cut is essential, once again cylinder mowers are usually preferred.

Additionally, and despite their general robustness, standard rotary mowers are not designed to handle extensive areas of tall, coarse grass, or scrub, where the use of more specialised equipment — such as flail mowers and brush cutters — is instead recommended. So, while rotary mowers are a strong all-round solution for most domestic lawns, they are not the tool of choice when it comes to precision turf management or heavy-duty cutting.

Summary

Rotary mowers are ideal for busy, family lawns used for a wide variety of leisure and recreational purposes. They’re affordable, easy to use, easy to maintain, and they’re suitable for use across a wide range of lawn and grass types. However for finer areas of grass and on scrubland, cylinder mowers, flail mowers, or brushcutters will likely prove preferable.

Cylinder Mowers

As the name suggests, a cylinder mower – sometimes called a reel mower – incorporates a cutting cylinder. If the mower is petrol or electric, the cylinder is powered by the engine. If the mower is a hand mower, the cylinder is connected via gears or chains to the rear wheels or roller, rotating as the mower is pushed forward. Irrespective of how the cutting cylinder is powered, it rotates on a horizontal axis, trapping and slicing each blade of grass, against a fixed bottom plate (bedknife). Unlike rotary mowers which cut with a machete like action, a well-maintained, cylinder mower cuts in a precise, scissor like manner. The result is a cleaner, more consistent and crisper cut.

The number of blades on the cylinder determines the quality of cut, with more blades delivering a finer cut. Most domestic cylinder mowers on sale in the UK today, feature up to six blades, and are ideal for residential lawns. Machines with a greater number of blades are available, but they are best suited to ornamental lawns and sports pitches, and typically the exclusive domain of turfcare professionals.

Some models employ a cartridge system, which allows the cutting cylinder to be swapped out for scarifying and aerating cartridges. This creates a truly multi-purpose machine, with a wide variety of applications throughout the gardening year.

Whilst cylinder mowers are inherently unsuited for cutting very long grass, they can cut lower than many rotary mowers. Some cylinder models are even able to cut below 5mm. Hence, cylinder mowers are the machine of choice for maintaining many sports surfaces, ornamental gardens, and other areas of fine grassland.

Advantages of a Cylinder Mower

Whilst rotary mowers dominate the UK lawn mower market, cylinder mowers remain a significant seller. Despite rotary machines today being more capable and more versatile than ever before, cylinder mowers still offer significant ‘stand out’ benefits:

- Quality of cut: A well-maintained cylinder mower will ‘cut’ each individual blade of grass in a scissor like manner, whereas as a rotary mower tends to ‘tear’. The result is that you can expect a cylinder machine to produce a crisper, cleaner cut;

- Striped finish: Most cylinder mowers employ a rear roller, to deliver a lustrous, striped finish;

- Reduced risk of scalping: The absence of wheels eliminates wheel marks, reduces the risk of scalping and distributes the weight of the mower across a greater surface area;

- Low cut advantage: Cylinder mowers can cut lower than most rotary mowers;

- Grass box visibility: On many cylinder mowers, the grass box is placed in front of the mower, and allowing you to easily see the volume of grass inside;

- Versatility: Cylinder mowers are truly versatile machines, and available as hand-powered, petrol-powered, mains electric and cordless battery-powered mowers;

- More than just a mower: Cartridge options allow many cylinder mowers to be repurposed for a wide range of applications, including scarifying, aerating, and de-thatching.

Cylinder mowers can today be found at many independent garden machinery showrooms across the land. Image Credit: Author

In addition to corded electric, petrol and even cordless models, many hand mowers also employ a cutting cylinder. Image Credit: Furbymama

Disadvantages of a Cylinder Mower

Like any technology, cylinder machines have their downsides too, and there’s a price to be paid for the fine cut they provide.

- Cost: Cylinder mowers are typically more expensive to purchase, reflecting their more complex construction and the use of precision components. You can also expect maintenance costs to be a little higher than for a comparable rotary mower;

- Long grass performance: Whilst a cylinder mower can cut lower than most rotary mowers, they are generally not well suited to use on areas with very long grass;

- Performance on uneven ground: Cylinder mowers perform best on level, well-maintained lawns, and are not recommended for use on uneven ground;

- Front mounted grass collector: While front-mounted grass boxes improve visibility and weight balance, they can become obstructive when mowing close to walls, fences, or garden features, limiting access and manoeuvrability in tight spaces;

- Product choice: The range of cylinder mowers available, is much reduced, when compared to rotary mowers;

- Ongoing adjustment: The blade-to-bedknife clearance must be inspected and adjusted regularly to maintain quality of cut. This demands more attention than the relatively forgiving blade systems, fitted to rotary models;

- Blade sharpening: Although cylinder blades are effectively self-sharpening during normal use, they will eventually require grinding by a specialist, a process that is more time-consuming and costly, than simply replacing or sharpening a rotary blade.

Summary

For the majority of homeowners, a rotary mower remains the most practical and cost-effective solution.

However, if your goal is perfection — a flat, manicured, surface with razor-sharp stripes and consistent finish — then a cylinder mower is essential. It’s the professional standard used on world-class golf courses, in sporting stadiums, and on ornamental lawns, where precision really matters. What’s more, many high-end cylinder models incorporate modular cartridge systems, allowing the cutting cylinder to be swapped out for scarifiers, aerators, or grooming units. This expands the mower’s functionality, turning it into a comprehensive turf management system — and helping to justify the initial investment.

So, while cylinder mowers may demand more from the operator, they

reward the effort with results no rotary mower can match.

Swing Tip Blades

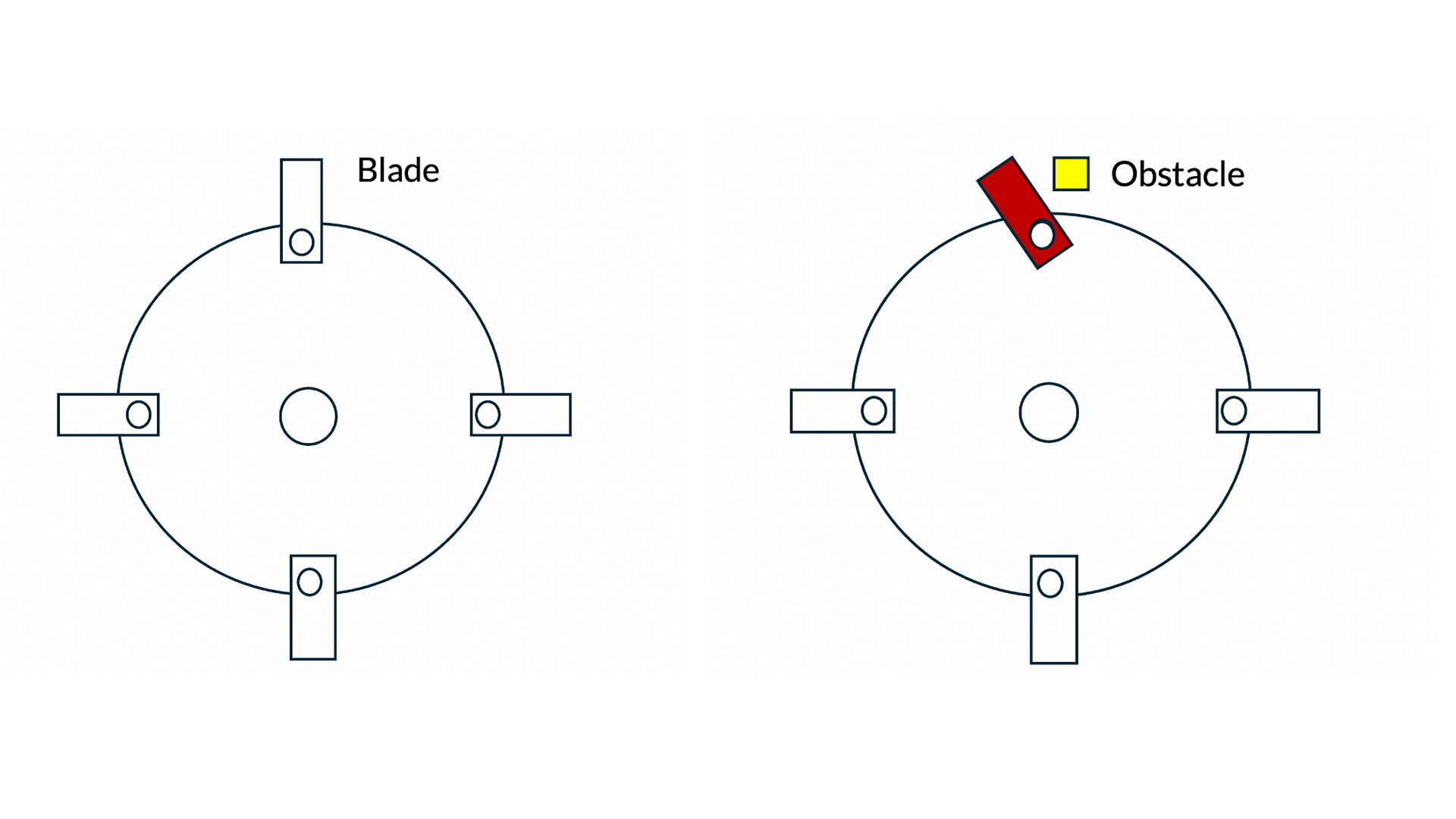

The swing-tip blade system — also known as a swing-back blade — is an evolution of the rotary mower. Rather than using a fixed, bar-type blade mounted directly to the crankshaft, swing-tip systems employ a rotating disc fitted with pivoting blades. This arrangement offers significant advantages over a standard rotary mower design:

- Impact protection and reduced risk of engine damage: When a mower equipped with swing tip blades encounters a solid object — such as a hidden rock, tree root, or garden debris — the pivoting blades fold back to absorb the impact, rather than delivering the full force of the impact to the crankshaft. This greatly reduces the likelihood of engine damage;

- Enhanced under-deck airflow and collection: The combination of the central disc and pivoting blades improves air circulation beneath the cutting deck. This creates a powerful upward draft, delivering a cleaner cut, whilst simultaneously improving collection, so more clippings are discharged to the grass collector, and fewer are left behind on the lawn.

Swing tip blades are today fitted as standard to many commercial mowers, and are also available on a growing range of consumer-grade machines. Typically, a machine equipped with swing tip blades will cost more than a comparable mower fitted with a standard bar blade. However, many homeowners and householders are happy to pay this premium, in return for a cleaner cut, and the reduced risk of accidental, crankshaft damage.

Schematic diagram showing a typical swing tip blade arrangement. In the LH diagram, the blades are free to move unencumbered. In the RH diagram, the red blade has hit an obstacle, causing it to swing back.

Image Credit: Author

An underside view of the cutting deck of TORO's mighty Timemaster, featuring a 76cm cutting path.

Image Credit: The TORO Company

Dual Blades

An advanced variation on the traditional rotary mower, dual-blade systems feature two parallel bar-type blades mounted side by side beneath a single deck. This configuration is typically found on larger walk-behind mowers engineered to deliver the cutting capacity of a ride-on mower, while retaining the manoeuvrability and footprint of a walk-behind machine.

Dual-blade arrangements, allow manufacturers to:

- Increase cutting width without dramatically enlarging the chassis;

- Reduce cutting time, particularly over wide, open lawns;

- Provide a cost-effective and viable alternative to lawn tractors and ride-ons, for use on larger gardens.

TORO's Timemaster machine is probably the best-known dual-blade mower.

Wheeled String / Line Trimmers

Wheeled string trimmers — sometimes simply called walk-behind strimmers — come in two primary configurations. Each is designed for specific cutting tasks beyond the scope of conventional mowers.

Compact Trimmers

These models combine a standard handheld line trimmer (or 'strimmer') with a lightweight, plastic wheeled frame, making them ideal for smaller city lawns and courtyard style gardens. Some models even offer detachable chassis designs, which allows the user to remove the trimmer for stand-alone operation. Black & Decker's Cordless Strimmer and City Mower is probably the best-known machine of this type.

Field Trimmers

At the other end of the spectrum are contractor grade, petrol and li-ion powered wheeled trimmers, which feature large rear wheels and are designed primarily for:

- Clearing dense undergrowth;

- Tackling thick, overgrown grass;

- Maintaining field edges, orchards, or roadside verges.

These machines offer superior reach and cutting power, especially on uneven terrain. However, they are unsuitable for precision lawn mowing due to their coarse cutting action and wide clearance. They are rarely if ever used on domestic lawns.

Sickle Bar Mowers

Designed for agricultural and semi-wild environments, sickle bar mowers — also known as scythe mowers — are built primarily for vegetation control, not lawn maintenance. These machines are ideal for:

- Paddocks and meadows;

- Orchards and rough pastureland;

- Clearing large swaths of tall grass, brambles, and/or light scrub.

Cutting Mechanism

The sickle bar mower utilises a reciprocating blade system, similar in principle to hair clippers or hedge shears. An oscillating top blade, slides back and forth over a fixed bottom blade, cutting vegetation cleanly at the base. Sickle bar mowers deliver:

- Efficient clearance of tall, dense growth;

- Minimal disturbance to surrounding vegetation;

- Cleaner cuts, relative to other large scale cutting solutions.

Some models are standalone. Others are part of a modular systems, where the sickle bar is one of several interchangeable attachments powered by a common power unit.

Limitations

Due to their size, cost, and coarse cut, sickle bar mowers are

unsuitable for most domestic lawns. However, they are the go-to solution for landowners and groundskeepers, tasked with

maintaining large areas of otherwise unmanaged land.

Mercedes Unimog with front and boom mounted flail mowers.

Image Credit:

Joost J. Bakker

Close up view of individual flails, fitted to the rotating drum of a flail mower.

Image Credit:

Alupus

Flail Mowers

Flail mowers are engineered for rugged performance in demanding environments where conventional mowers fall short. The name comes from their distinctive use of 'flails' — also referred to as knives or blades — mounted on a horizontal, high-speed rotating drum. As the drum spins, centrifugal force propels the flails outward, enabling them to shred through grass, brambles, and dense vegetation, with a pulverising action.

Advantages

Each flail is attached to the drum via a pivoting linkage, allowing it to swing freely. This design provides several mechanical advantages:

- Shock absorption: When a flail strikes a solid object (e.g., rocks, stumps), it retracts on impact rather than transferring the force to the drum or powertrain;

- Enhanced safety: Flail mowers are far safer to use in areas potentially littered with debris, such as roadside verges, embankments, and scrub;

- Superior mulching: The aggressive shredding action produces finely chopped material, which decomposes quickly, to reduce and frequently eliminate the need for collection.

In most cases, flail mowers are designed to be mounted on to vehicles, connected via a 3-point linkage system and powered by the vehicle's

PTO (Power Take-Off) shaft. These machines are commonly

towed behind or offset to the side, dependent upon application. Flail mowers are again rarely used in a domestic context.

Summary

For the vast majority of UK gardens, a rotary mower remains the most practical and popular choice. Whether you're opting for a hover, rear-roller, or wheeled variant, rotary mowers offer an ideal balance of affordability, ease of use, and low maintenance. With thousands of petrol, electric, and cordless models available, there’s a rotary mower to suit almost every garden — from a town house, to a manor house.

For homeowners with a slightly greater budget, models equipped with swing-tip blades are well worth considering. Combining enhanced durability, superior cut quality and collection performance, they’re usually found at the premium end of the market.

However, if you're seeking that immaculate, striped, bowling-green finish — then a cylinder mower is essential. The gold standard in cut quality, cylinder mowers use a scissor-like cutting action that delivers a cleaner, sharper, and more consistent finish than any other type of mower. While cylinder machines are generally more expensive to purchase and require more maintenance, their cutting performance is in a league of its own. For many amateur gardeners and horticultural professionals alike, the results justify the initial investment. Today, tens of thousands of British gardeners wouldn’t consider using anything else.

Finally, whilst flail mowers, sickle bar mowers and field trimmers are ideal for specialist horticultural applications, they are inherently unsuitable for domestic lawns.